Navigation

Stream of Sand Behaves Like Water: Research opens up new experimental territory

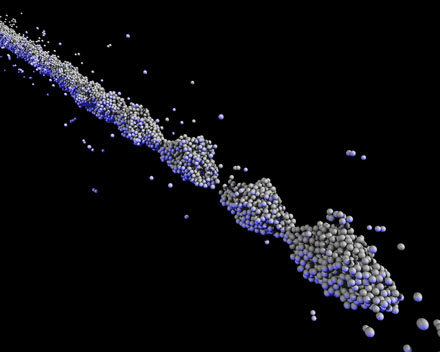

University of Chicago researchers recently showed that dry granular materials such as sands, seeds and grains have properties similar to liquid, forming water-like droplets when poured from a given source.

|

| In a first-time accomplishment, physicists from the Materials Research Science and Engineering Center at the University of Chicago used high-speed photography to measure minute levels of surface tension and detect droplet formation in flows of dry granular materials. The finding could be important to industries that use "fluidized" dry particles for oil refining, plastics manufacturing, pharmaceutical production and other mechanized processes. Photo and text: Helge F. Gruetjen, John R. Royer, Scott R. Waitukaitis, and Heinrich M. Jaeger, The University of Chicago |

University of Chicago researchers recently showed that dry granular materials such as sands, seeds and grains have properties similar to liquid, forming water-like droplets when poured from a given source. The finding could be important to a wide range of industries that use "fluidized" dry particles for oil refining, plastics manufacturing and pharmaceutical production.

Researchers previously thought dry particles lacked sufficient surface tension to form droplets like ordinary liquids. But, in a first-time accomplishment, physicists from the Materials Research Science and Engineering Center at the University of Chicago, led by Professor Heinrich M. Jaeger, used high-speed photography to measure minute levels of surface tension and detect droplet formation in flows of dry granular materials.

The science journal Nature reports the finding in its June 25 issue. The materials research center at the University of Chicago is supported by the National Science Foundation.

Until recently, studies of so-called "free falling granular streams" tracked shape changes in flows of dry materials, but were unable to observe the full evolution of the forming droplets or the clustering mechanisms involved.

"Previous studies of granular streams were able to detect clustering by performing experiments in vacuum and were able to establish that the clustering was not caused by the drag from the ambient air," said Jaeger. "However, the cause of the clustering remained a mystery."

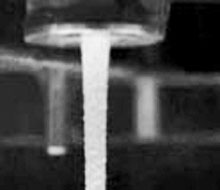

But in this new experiment, researchers measured nanoscale forces that cause droplet formation using a special co-moving apparatus devised for a high-speed, $80,000 camera that captures images much like a skydiver might photograph a fellow jumper in free fall.

|

| Image from video by: John Royer and Heinrich Jaeger, The University of Chicago |

In this high speed video of a freely falling granular stream, viewers see a specially designed camera apparatus move alongside an initial acceleration period and track the formation of grain clusters, similar to the formation of droplets for a water stream falling from a faucet.

They observed falling 100-micrometer-diameter glass beads, or streaming sand, and found that forces as much as 100,000 times smaller than those that produce surface tension in ordinary liquids could cause droplet formation in granular streams and cause these dry streams to behave like an ultra-low-surface-tension liquid.

John Royer, the graduate student in physics at the University of Chicago, who developed the apparatus, and his colleagues also directly measured grain-to-grain interactions with an atomic force microscope.

"At first we thought grain-grain interactions would be far too weak to influence the granular stream," said Royer. "The atomic force microscopy surprised us by demonstrating that small changes in these interactions could have a large impact on the break up of the stream, conclusively showing that these interactions were actually controlling the droplet formation."

Researchers say understanding how dry materials coalesce could create greater efficiencies in their transportation and manipulation. The pharmaceutical production of pills, for example, could benefit by pouring equal amounts of a drug into a capsule every time while greatly reducing waste.

"Estimates show that we waste 60 percent of the capacity of many of our industrial plants due to problems related to the transport of these materials," said Jaeger. "Hence even a small improvement in our understanding of how granular media behave should have a profound impact for industry."

The researchers write in their report that these "experimental results open up new territory for which there currently is no theoretical framework."

"Our experiments ask two questions for which currently there is no established answer," said Jaeger. "Both questions are about how a liquid breaks apart. How does the break-up proceed in the ultra-low surface-tension limit and what happens in the ultra-low temperature limit when particles cease to move relative to each other?

"It is quite remarkable that a granular stream consisting of macroscopic particles provides a model system to explore it."

This information is from the National Science Foundation (NSF), a independent federal agency that supports fundamental research and education.

Note:

Search

Latest articles

Agriculture

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

Air Pollution

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

Biodiversity

- It is time for international mobilization against climate change

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

Desertification

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- UN Food Systems Summit Receives Over 1,200 Ideas to Help Meet Sustainable Development Goals

Endangered Species

- Mangrove Action Project Collaborates to Restore and Preserve Mangrove Ecosystems

- Coral Research in Palau offers a “Glimmer of Hope”

Energy

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

- Wildlife Preservation in Southeast Nova Scotia

Exhibits

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

- Coral Reefs

Forests

- NASA Satellites Reveal Major Shifts in Global Freshwater Updated June 2020

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

Global Climate Change

- It is time for international mobilization against climate change

- It is time for international mobilization against climate change

Global Health

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- More than 400 schoolgirls, family and teachers rescued from Afghanistan by small coalition

Industry

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

Natural Disaster Relief

- STOP ATTACKS ON HEALTH CARE IN UKRAINE

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

News and Special Reports

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- STOP ATTACKS ON HEALTH CARE IN UKRAINE

Oceans, Coral Reefs

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- Mangrove Action Project Collaborates to Restore and Preserve Mangrove Ecosystems

Pollution

- Zakaria Ouedraogo of Burkina Faso Produces Film “Nzoue Fiyen: Water Not Drinkable”

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

Population

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

Public Health

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution

Rivers

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- Mangrove Action Project Collaborates to Restore and Preserve Mangrove Ecosystems

Sanitation

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution

Toxic Chemicals

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- Actions to Prevent Polluted Drinking Water in the United States

Transportation

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- Urbanization Provides Opportunities for Transition to a Green Economy, Says New Report

Waste Management

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution

Water

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution

Water and Sanitation

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution